In the world of vintage automotive restoration, there is a distinct difference between a vehicle that looks good from ten feet away and one that feels right from the driver’s seat. We often see classics that have been given the “glossy” treatment—fresh paint, shiny chrome, and new upholstery—but underneath the skin, they remain tired, disjointed, or simply unfinished.

It is a common plight of the “fresh restoration,” where the cosmetics write checks that the mechanics can’t cash. This was the exact scenario facing Legacy Overland when a 1968 Ford Bronco, dubbed Project Moulton, rolled into their shop.

It was clearly loved and earnestly restored, yet it lacked that final layer of cohesive craftsmanship that separates a good truck from a great one.

Legacy Overland, a name synonymous with obsessive attention to detail and rugged aesthetic perfection, took on the challenge not to rebuild Moulton, but to perfect it.

The goal was to take the solid foundation laid by its previous owner and elevate it to the shop’s exacting standards of drivability, reliability, and finish. This wasn’t about reinventing the wheel; it was about ensuring the wheel didn’t wobble.

The result is a first-generation Bronco that stands as a testament to the power of refinement—a vehicle that is honest, simple, mechanical, and finally, finished the right way. The first order of business was to address the unseen gremlins that often plague vintage builds. The team dove into the electrical system, untying knots of wiring hidden behind new panels and correcting a heating and A/C system that was plumbed but functionally useless.

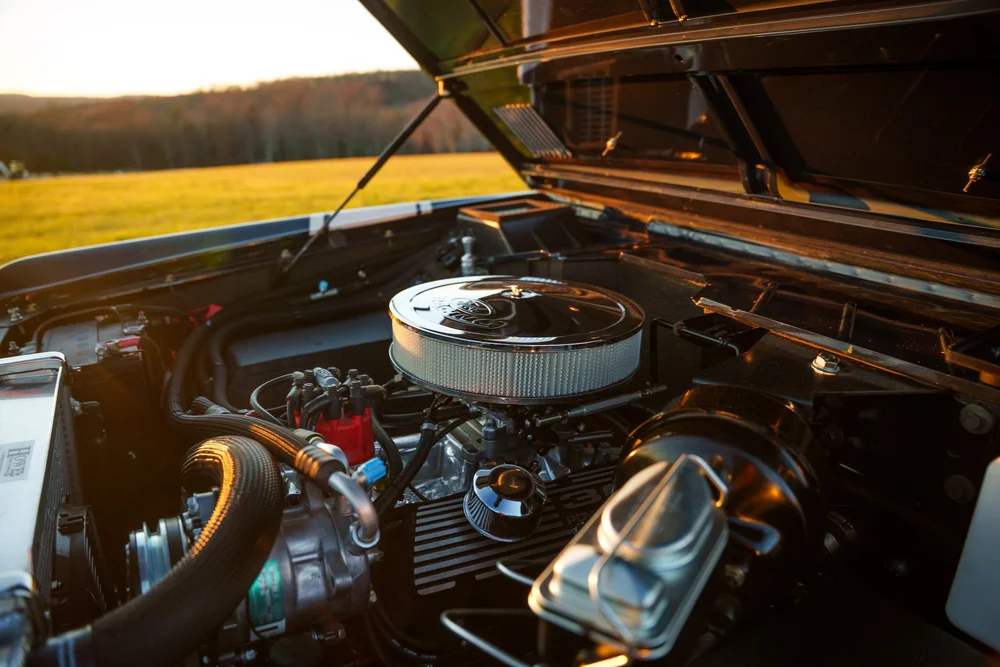

They modernized the wiring throughout the cabin and engine bay, installing new fused relay systems, timer switch modules, and a proper distribution block. This isn’t the sexy work that makes for viral Instagram posts, but it is the critical work that ensures the lights turn on, the engine starts, and the truck doesn’t leave you stranded on a backroad.

Mechanically, the Moulton received a significant auditory and performance upgrade. While the existing exhaust looked the part, it didn’t perform or fit to Legacy’s standards.

The team installed a complete performance exhaust system featuring new Scott Drake headers, a new muffler, and custom piping that finally lets the Ford V8 breathe as it should.

Under the hood, updated vacuum routing, a new engine dipstick, and fresh hardware throughout ensured that the engine bay looked as crisp as the exterior.

Speaking of the exterior, the most visually striking addition is the custom soft top. The previous aftermarket unit failed to honor the Bronco’s iconic boxy proportions, so Legacy Overland crafted a hand-built soft top from bespoke molds.

This fresh canvas top features improved structure and sealing, giving the Moulton a silhouette that is both rugged and refined. The bodywork was also treated to a multi-stage detailing and surface refinement, correcting panel alignment and ensuring that the first-generation lines were as sharp as they were in 1968.

Inside, the cabin detailing was improved, with stress points reinforced for durability and behind-dash wiring cleaned and routed properly. Every switch, every gauge, and every circuit was road-tested and validated, from the fuel-prime circuit to the HVAC controls.

Project Moulton is no longer just a pretty face; it is a fully realized machine, ready for the next 50 years of adventure.

- Monar Unveils Hi‑Fi Canvas Speaker – Transforming Music into Paintings to Inspire Artistic Living with Studio‑Grade Sound - March 3, 2026

- All The Best New Menswear Pieces from the Relwen Spring/Summer 26 Drop - March 3, 2026

- A Toast To Workspace Perfection: The BALOLO Setup Cockpit Monitor Stand Large Whiskey Barrel Edition - March 3, 2026